HI-FLO Engineered Weeper

Preferred Engineering introduces the HI-FLO Engineered Weeper System that really works.

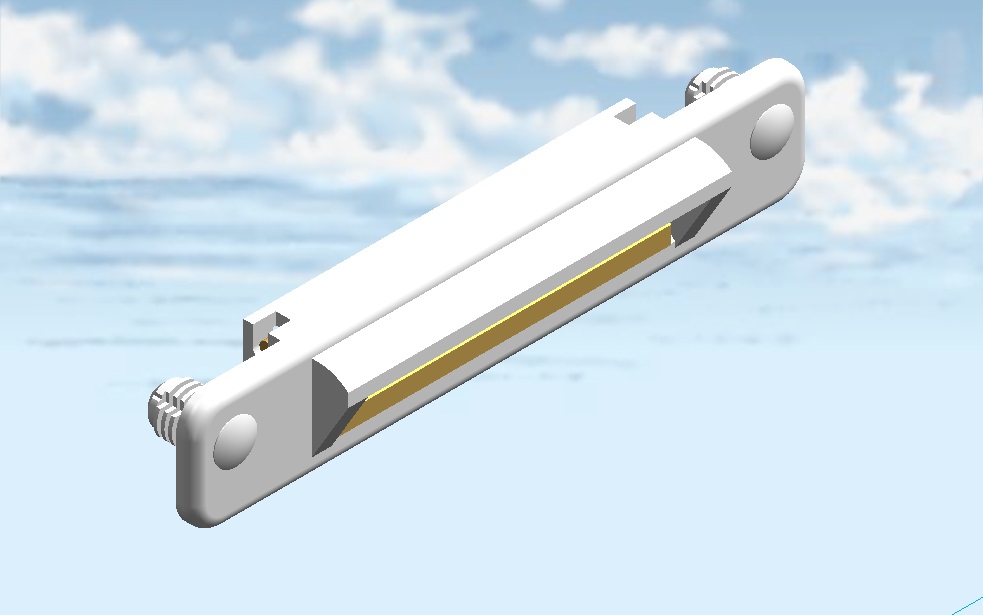

The HI-FLO reed valve (one way valve) is designed to operate in the low pressures found in window and door sills. Molded from non-hydroscopic material, the HI-FLO reed valve will not retain moisture, which can cause swelling and malfunction in standard nylon-based weepers. The valve remains closed, preventing air and insects from entering the home until the interior water pressure (caused by water infiltration) exceeds the exterior wind pressure, allowing the water to escape. An integrated hood covers the reed valve and protects it from being held closed by water shedding down the face of the window.

Two Christmas tree style fasteners are incorporated to securely attach the weeper to the window frame. Special attention has been taken with this fastener design to ensure that the weeper cannot be knocked from the window and lost in shipping, eliminating costly time consuming service.

HI-FLO weepers can be mounted at any angle up to 45° and still maintain optimal drainage performance.

This precision-engineered product is a small price to pay for peace of mind. Water damage and costly service repairs can be a thing of the past. Don’t get caught up, in the misconception that

you have to sacrifice air performance for water performance, this is not the case! View our web site: at www.preferred-eng.com to see more information on how this weeper works with any window and how it can be especially beneficial when used with the twin-tiered drainage technique required on tilt in sliders.

|

Hi-Flo Weepers

|

|

|

|

Demystifying the drainage debate Myth #1: The Preferred development team has engineered a product that alleviates this problem. Their HI-FLO drainage system maximizes the flow rate that results from the low pressures found in window and sliding door sills. The system is specially engineered to give optimal flow rates and drainage performance, even when working on a 45º angle. Our one-way valve weeper assembly snaps on right over the hole. This prevents air from being pushed into the window, while allowing water to be pushed out. Other companies sell what they call ‘weep covers’, but they’re merely little hoods that cover a hole and make it invisible – but have no valves on the covers. Myth #2: By merely factoring the density of the water at 62.5 lbs./ft. and multiplying it by the height of a window sill, manufacturers can determine how high their sill needs to be in order to overcome outside wind pressure. “If you have proper drain holes, channeled in the right way, you will ensure that your window passes the water test. There’s really no magic involved – it’s just regular old physics.” When a window is tested, the amount of water sprayed on it is quite excessive (twice as much pressure as ever recorded in North America). Not surprisingly, this causes water to leak in, because all windows will leak to a certain extent. But that water has to be channeled back out – and it has to drain out at least as quickly as it’s coming in – or it’s going to start backing up. Preferred’s HI-FLO Weepers were designed with this in mind. After calculating the flow rate and pressure required, we determined what size opening was needed to allow the same amount of water coming in to be drained out. If you have a tiny hole and you want the water to exit at a certain speed, more pressure needs to be applied. When you have a bigger hole, more water can be drained at less pressure. Our HI-FLO drainage system was engineered so that water could flow out under low pressure.” Hanging drainage myths out to dry Innovative products like the HI-FLO drainage system are evaporating old drainage myths and giving window manufacturers the opportunity to minimize water damage and costly service repairs, without sacrificing air performance for water performance. The company’s philosophy this way: “We’re a product development company first, and a manufacturer second. We supply on time and make a quality product, but we’re always developing something new. We’re always looking to make new and better products and improve on what the industry considers standard.” |