Get unparalleled performance with PARALLEXTM™

The Parallex™ hardware is an entirely integrated hardware operating system that provides functionality that was never before possible.

The patented Parallex system offers unmatched ease of use allowing tilt/slide and multi-lock functions to be achieved with a single operating lever. Parallex can also be used for casement and awning windows, completely eliminating the use of a crank, providing an uncluttered, clean finished appearance without any mechanism to get tangled up in blinds or drapes.

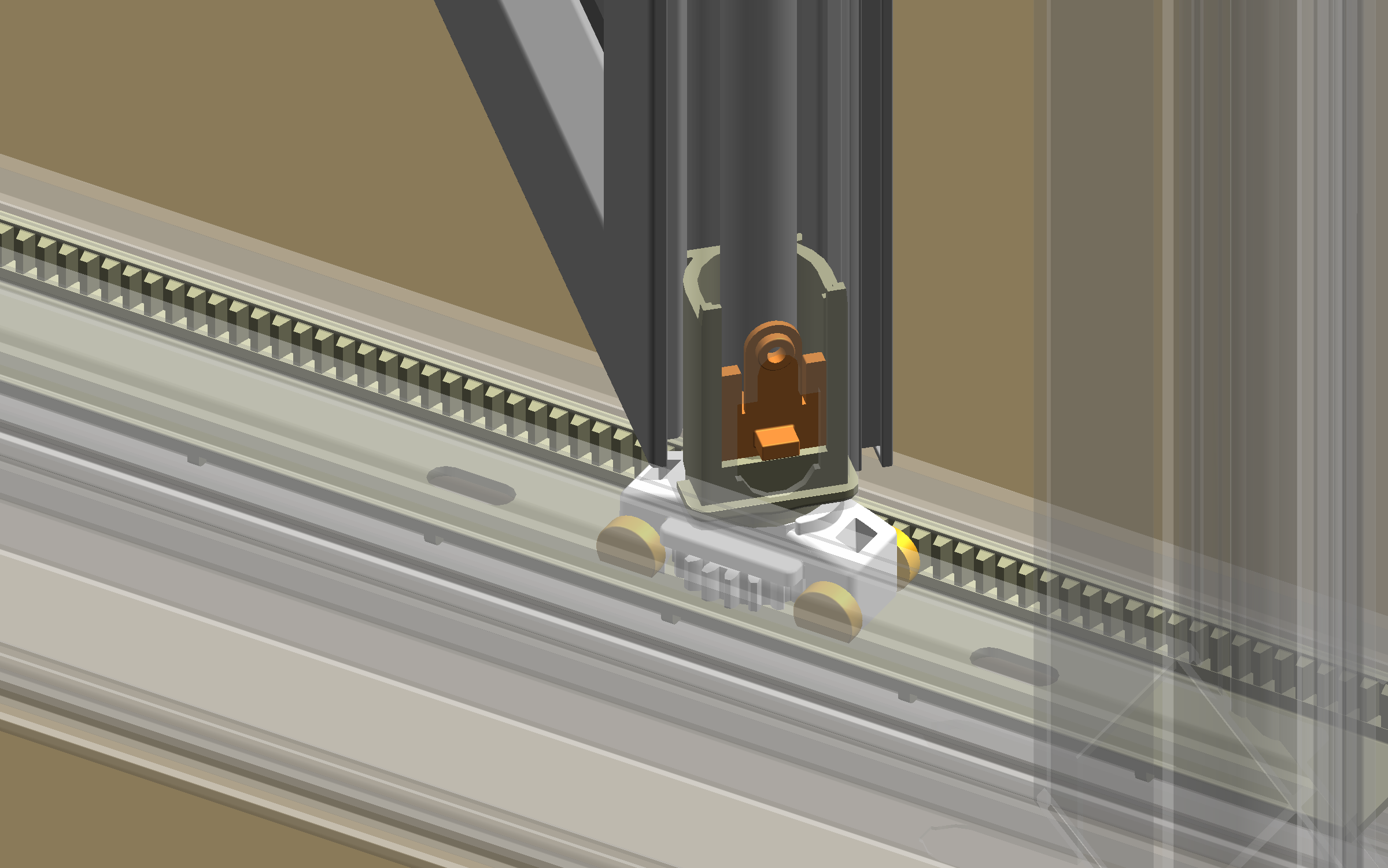

The Parallex system consists of durable toothed composite engineered tracks made of DuPont™ Zytel® DMX, robust carrier shoes complete with tandem long life brass wheels and a pivot shaft that runs through the sash. A self-lubricating bearing in the carrier shoes meshes with the teeth in the guide track ensuring parallel alignment of the sash. These components work together to form a rack and pinion mechanism that holds the sash parallel to the frame while doubling as a hinge.

The rack and pinion design prevents sash sag in casement windows by isolating the cantilevered load of the glass. Conventional casement windows rely on the sash to resist these forces, causing it to twist resulting in poor fit and reduced efficiency over time. Parallex solves this

problem and allows sashes to be manufactured with triple-pane glass and up to 36” x 72” in size.

Slider windows made with Parallex slide easily and can be tilted inwards with one hand. Because the rack and pinion system keeps the sash parallel and secured to the frame at all times, there is no need to lock the sash before tilting inward. Double-hung windows utilizing Parallex

hardware have all the same features as slider windows, but also include an integrated sash balance to prevent racking

Benefits of the Parallex™ System

Window Manufacturers

• Increased profits: much of the Parallex hardware is generic to casement, hung and slider windows and fewer profiles need to be inventoried.

• In some applications, Parallex can cost less than half the price of alternative less effective hardware

• Ease of system assembly means increased worker productivity

• Significant product differentiation

• Desirability of features makes windows using Parallex hardware more attractive to consumers

• When used in conjunction with the Slide‘N’Hide rollaway screen, significant savings on screen remakes and service calls from shipping damage can be achieved.

• Parallex meets all AMMA and CSA specifications for air, water, structural, forced entry and ease of operation.

Dealers and Distributors

• Significant product differentiation;

• Unique features make windows with Parallex hardware more attractive to homeowners

• Premium window features = higher margins

• System quality and ease-of-use virtually eliminates service calls.

Homeowners

• Smooth almost weightless one finger operation.

• Easy to clean

• Greater safety and reliability

• Increased ventilation

• Operating sashes up to 36” x 72” offer more daylight

• Integrated Slide‘N’Hide screen system disappears when not needed, offering a clear unobstructed view with more daylight

• Quick simple egress in the event of a fire

• Especially suited for use by the elderly or physically challenged consumer

• No crank handles to tangle in blinds or drapes

|

Parallex™

|

|

|

| The Parallex hardware system is the easiest to operate, most dependable system available. Parallex is revolutionary in that it has reinvented how traditional window hardware functions. Adaptable to casement, awning, slider and double hung windows, it minimizes inventory, assembles quickly and offers the consumer sashes that don’t fall out of their tracks. Parallex is effortless to operate and lock with one hand. The lock/tilt mechanism offers especially useful operating features for tall sashes, as the handle can be positioned anywhere. It offers added security, uncomplicated, quick egress and improved ventilation.

Build a Parallex casement in less time than a conventional casement (approximately less than half an hour) Conventional casements require a fair amount of routing or punching to provide access for the crank mechanism to reach the sash (this slot also results in air leakage). In addition, there is a substantial amount of bolt on components such as snubbers and keepers that need to be accurately placed. The Parallex hardware consists of a pair of tracks that are cut to size with a simple cut-off saw, slid into the head and sill prior to welding then fastened with a single screw each. The frame and sash are cut welded cleaned and glazed as normal. The shaft is fastened to the sash with one screw at each end and a cosmetic cover is snapped over that. The handle and its keeper are fastened to the sash and frame with two screws each into holes that were punched after cutting. The only additional component is the linkage bar that is attached to the sash and frame with two more screws. These components are all positioned at the ends of the sash and frame and do not require time consuming measurements. In other words very easy to make and does not require the labor to be extensively trained. Since the Parallex hardware cannot sag there needs to be some adjustment in the hardware to square the sash to the frame once the sash is installed. This is simply a screw built into the track that can be turned to adjust the angle of the sash to make it parallel to the frame on all sides. Field adjustment for out of square window openings and not so perfect installers can be achieved using the same method |