Get superior flexibility and safety with Tilt’N’Slide™

Tilt‘N’Slide™ is the original tilt-slider hardware, and is still the safest, most reliable and trustworthy hardware available to fabricators today.

Preferred Engineering Products’ award-winning Tilt‘N’Slide window hardware system is the first system designed to allow double or single hung tilt profiles to be successfully converted to build double or single tilt-in sliders. This design allows the sashes to be locked to the frame and

swung into the room for safe easy cleaning of the exterior glass from inside the house and maximum ventilation. Because the entire sash is allowed to swing inwards, windows can be manufactured to facilitate the required egress dimensions in a window half the size.

Not all tilt-in window hardware is created equal. Tilt‘N’Slide is the safest tilt-in hardware on the market today and securely locks the sash to the frame by means of a precision engineered braking vice before the sash can be tilted. This positive locking system essentially freezes the pivot

bars in position allowing the sash to safely swing inwards, without any fear of it falling from the frame and injuring the homeowner. This safety feature also eliminates liability issues for the manufacturer and allows windows with sashes up to 48″ x 72″ to be safely tilted inwards.

Unlike Tilt’N’Slide, other systems use an expansion or friction mechanism that applies pressure between a cam shoe and the frame. These systems use plastics for their braking devices which tend to be slippery and make friction difficult. Friction-based systems require the window

to tilt inwards in order to engage the cam, leaving a period of time where the sash is in a precarious unsupported position and could fall out of the frame. Because the sash is not supported, it can drag across the frame, damaging the weather seal and impairing the performance

of the window.

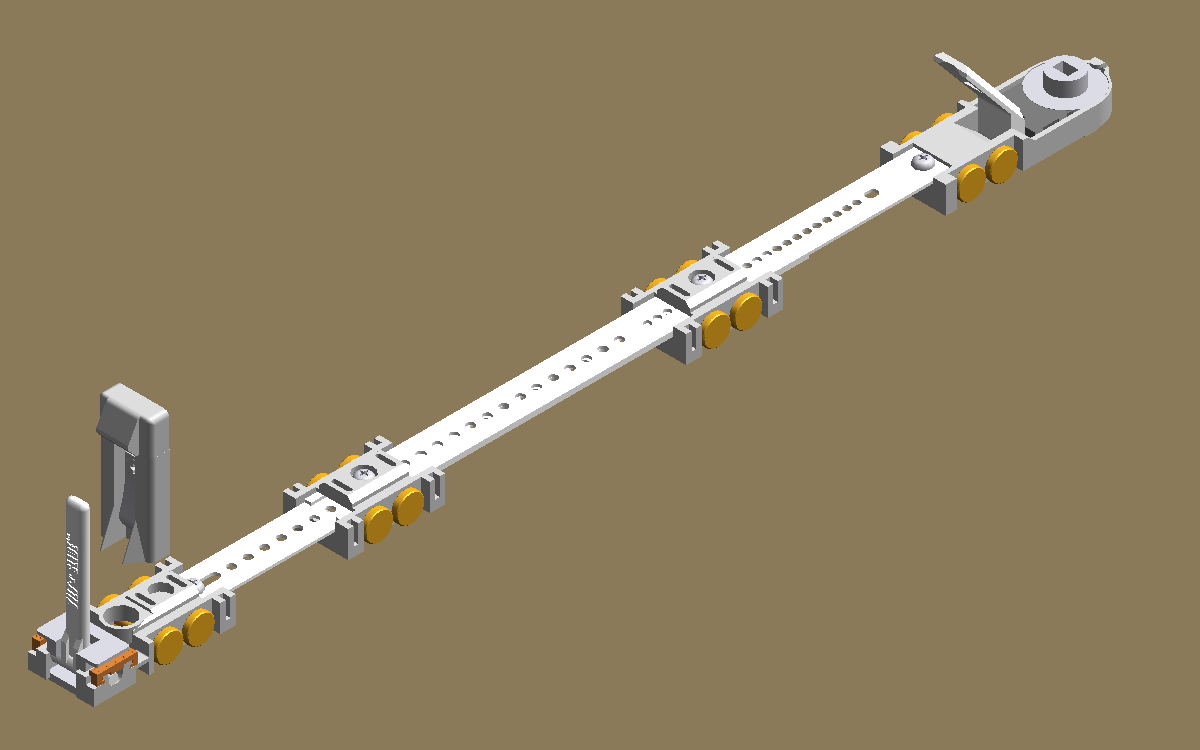

The Tilt‘N’Slide system is manufactured of high quality materials in a modular structure that can be custom fitted to almost any profile. Parking blocks integrated on top of the carrier shoes support the sash and distribute its weight evenly. The unique carrier shoe system integrates brass

quad rollers which glide effortlessly inside the track and maintain the sash at a constant height from the sill, protecting the sash and weather seal from damage.

An optional anti-swing lock made holds the sash in the fully tilted-in position, permitting maximum ventilation with no risk of the sash closing unexpectedly. A patented band brake made of high-performance DuPont™ Delrin® is integrated into the pivot shoe and is activated by pulling a

small lever once the sash has been tilted to the desired position. The brake will resist 10ft-lbs of torque before slipping in the event of an overload, automatically releasing the anti-swing lock and preventing damage to the sash.

Benefits of Tilt’N’Slide™

Window Manufacturers

• Can be incorporated into existing double or single hung tilt profiles, so there’s no need to re-tool

• Increased profits: Ease of assembly means increased worker productivity

• Brass quad-roller design keeps sash at a constant height, maintaining weather seal integrity

• Caliper lock safely permits sash sizes up to 48″ X 72″

• Can be built with up to three operating tilt sashes

• Features and safety aspects make Tilt‘N’Slide desirable to homeowners

• Available in: White, Blue White, Brown, Beige and Bronze

• Limited lifetime warranty

• Tested to ensure continued performance for over 40 years

• Marketing support and training

Dealers and Distributors

• Product differentiation

• Functionality and safety features make windows with Tilt‘N’Slide hardware more desirable to homeowners

• Quality of manufacture and ease of operation virtually eliminates service calls

• Increased margins with premium product

Homeowners

• Safest tilt-in window hardware on the market

• Window is firmly locked in position with a caliper brake before tilting inwards; sash sag is eliminated preserving the weather seal from damage

• Swing-in feature allows for easy cleaning, emergency exits, and maximizes ventilation

• Anti-swing feature stops tilted sash from being moved by the wind

• Brass long life quad-roller system maintains the sash at a constant height, reducing wear to the weather seal and preserving performance

| Tilt‘N’Slide™ . |  |

|

|

Preferred Engineering Products’ award-winning Tilt‘N’Slide window hardware system is the first system designed to allow double or single hung tilt profiles to be successfully converted to build double or single tilt-in sliders. This design allows the sashes to be locked to the frame and swung into the room for safe easy cleaning of the exterior glass from inside the house and maximum ventilation. Because the entire sash is allowed to swing inwards, windows can be manufactured to facilitate the required egress dimensions in a window half the size.

Not all tilt-in window hardware is created equal. Tilt‘N’Slide is the safest tilt-in hardware on the market today and securely locks the sash to the frame by means of a precision engineered braking vice before the sash can be tilted. This positive locking system essentially freezes the pivot bars in position allowing the sash to safely swing inwards, without any fear of it falling from the frame and injuring the homeowner. This safety feature also eliminates liability issues for the manufacturer and allows windows with sashes up to 48″ x 72″ to be safely tilted inwards.

Unlike Tilt’N’Slide, other systems use an expansion or friction mechanism that applies pressure between a cam shoe and the frame.

These systems use plastics for their braking devices which tend to be slippery and make friction difficult. Friction-based systems require the window to tilt inwards in order to engage the cam, leaving a period of time where the sash is in a precarious unsupported position and could fall out of the frame. Because the sash is not supported, it can drag across the frame, damaging the weather seal and impairing the performance of the window.

|